Lifting hook

Lifting hook

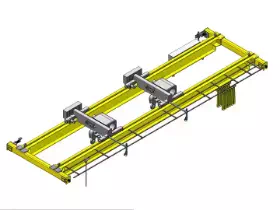

This crane is developed through the assimilation of advanced foreign technology, guided by modular design principles and supported by modern computer-aided methods. Utilizing optimized and reliable design approaches, it incorporates imported configurations, new materials, and advanced manufacturing technologies. Key features include light weight, broad applicability, energy efficiency, environmental friendliness, minimal maintenance, and high technological content.

The hoisting mechanism strictly follows FEM standards. Its design, production, and inspection comply with the latest national standards while equivalently adopting international norms such as FEM, DIN, and IEC. Key components include a high-precision, hard-tooth-surface reducer gear, steel drum/reel, forged wheels, and a variable-frequency speed control system.

Main Features

1. Long service life: 30–50 years

2. Easy installation and maintenance

3. Reasonable structure with high rigidity

4. Inverter-based variable speed control

5. Operation via cabin or remote control

6. Customizable lifting attachments (e.g., magnet, grab, C-hook)

7. Standard safety devices including travel limit switches and load limiting systems

Structural Advantages

The main beam adopts a lightweight, bias-rail box-type structure, connected to the end beams with high-strength bolts for easy transport.

A patented U-shaped main beam, formed hydraulically, ensures both durability and an aesthetically pleasing profile.

Constructed from Q345-B steel plate.

Drive & Trolley System

The trolley employs a space-saving, open compact winching structure (or a new-style hoist trolley for medium/low tonnage).

Travel mechanisms for both the crane and trolley feature European-style three-in-one drives with hardened gear reducers. This design is compact, quiet, leak-free, long-lasting, and helps reduce building height and costs.

Full variable-frequency control ensures smooth, impact-free operation. It enables low-speed heavy-load and high-speed light-load movement, improving energy efficiency.

Operation Cabin

Attractive cabin frame

Equipped with a seat and two adjustable consoles

Accessories include an alarm system, energy-efficient lighting, wipers, and blinds

Safety Features

Overload protection device

Durable polyurethane buffers

Crane travel limit switches

Undervoltage protection

Emergency stop system

PLC compatibility (optional)

Current overload protection system

This overhead crane is widely applicable across industries including machinery manufacturing and assembly, petrochemicals, warehousing and logistics, power construction, paper manufacturing, and railways.

Our Services

Pre-Sales Support

Our professional team ensures an optimal purchasing experience through dedicated one-to-one service. We guarantee high-quality products and short lead times, backed by strong production capacity, skilled personnel, and rigorous pre-delivery inspections.

After-Sales Service

Free to contact us:

1. One year warranty for whole machines

2. Providing free quick-wear part

3. Low charge for continue maintenance when warranty is expired

4. Exclusive engineer support at any time.

5. Highly professional training to end-users